C-1

U.S. Navy photo

Another view of Octopus on the building ways at the Fore River Shipbuilding Company, 1906. The Octopus was the first twin propeller submarine commissioned into the U.S. Navy, starting a trend that would last until 1953.

U.S. Navy photo

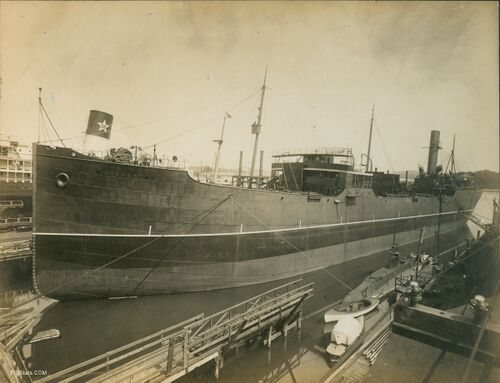

Octopus is shown here alongside a Fore River Shipbuilding dock in Quincy, MA., fall of 1907. Work to complete the Octopus for Navy acceptance is still ongoing, despite her having successfully passed the Navy demonstration the previous fall. The large ship next to her is the Steamship Everett, a collier built for the New England Coal & Coke Company that was delivered on October 19, 1907. This places the date of the photo to slightly before that date.

Photo in the private collection of Ric Hedman.

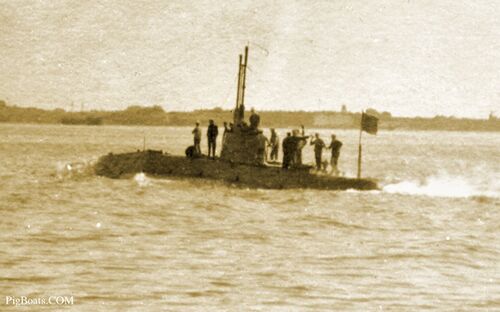

Octopus running at high speed, possibly in Narragansett Bay, Rhode Island, 1908-1909. This is likely Octopus' maximum speed of 11 knots. The men topside are only inches from the water and are in a precarious position if anything unexpected happens.

Photo from the collection of MMCM(SS) Rick Larson, USN (Ret.)

In another photo taken a few minutes after the one above, Octopus is seen entering a harbor, possibly Newport, R.I. or Norfolk, VA., 1908-1909. She is now at a much slower speed and her freeboard has increased slightly, making the men's position topside a little safer.

Photo from the collection of MMCM(SS) Rick Larson, USN (Ret.)

Octopus early in her career, probably 1906-1909, location unknown. Some small platforms have been temporarily rigged to the side of the superstructure fore and aft. Their purpose is unknown.

Photo in the private collection of Ric Hedman.

Octopus surfacing after a submerged run, possibly in Cape Cod Bay off Provincetown, MA., 1908-1910. She would still be running on the battery at this point, and would not start her engines until she was in full surface trim.

Photo in the private collection of Ric Hedman.

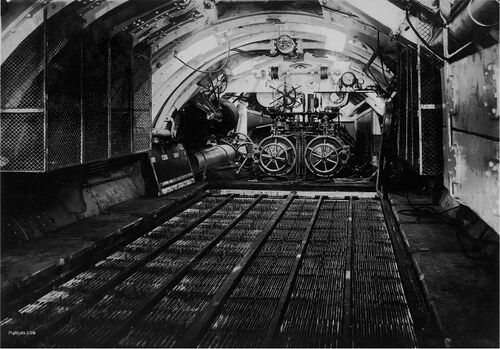

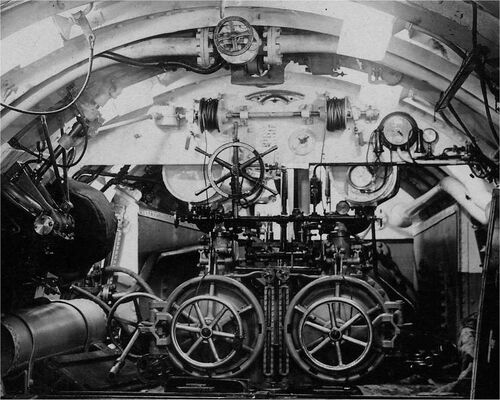

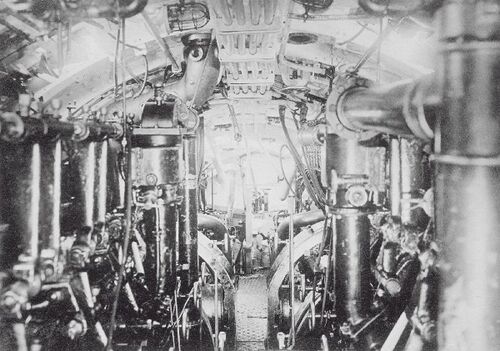

The battery compartment and torpedo tubes of the C-1, approximately 1912. The battery is an Edison Model 23-W, alkaline battery. It consists of 120 cells and had a capacity of 2550 Amps at a 3 hour discharge rate.

The wooden planks that cover the battery have been removed to show the individual plates and if you look closely you can see the small wood wedges (called cribbing) that hold the plates the designed distances from each other. When the decking is replaced it is screwed down and covered with a canvas that is shellacked down to make the deck waterproof. The shellack gives the decks a green color. With the deck in place the reload torpedoes and their storage skids would be in place on top of the deck.

The C-class submarines did not have individual watertight compartments. The entire boat, forward to aft, was one big compartment.

U.S. Navy photo

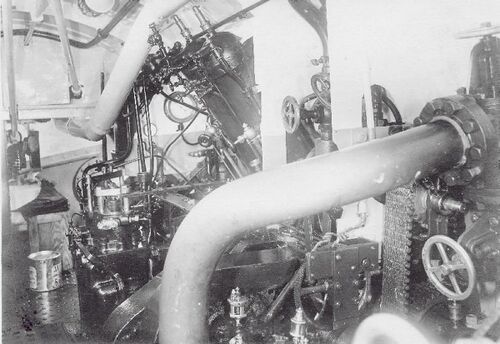

Detail from the above image. C-1 torpedo tubes showing the torpedo loading cable winches, sight glasses and associated piping and bow cap opening and closing hand wheel. A reload torpedo was positioned in front of the open tube door and a cable reeved through the pulley over the top center of each door from the winches seen above, and then to the rear of the torpedo.

On the outboard side of each winch drum are engaging handles to lock the drums onto a rotating shaft so you could only turn the selected winch drum and not the other. There is a long shaft running to what must have been a turning handle on the port side of the submarine but is obscured by anchor windlass motor gearing.

To the right of the starboard winch drum you can see an early interior communication sound powered phone system. It isn't clear if there are two handsets for listening but most likely you spoke into one and listened on the other. The cabling for these seems to come out of the large dial with the handsets on either side. It may be a way to dial specific stations in the submarine.

The valve handle in the top center is the "Forward Main Ballast Vent" opening and closing handle. When you dove someone had to open and close this valve to vent the tank of air.

The sight gauges between the tubes show how much water is in each tube. You want to make sure the tube is dry before opening, especially since the battery is just a few feet away.

U.S. Navy photo

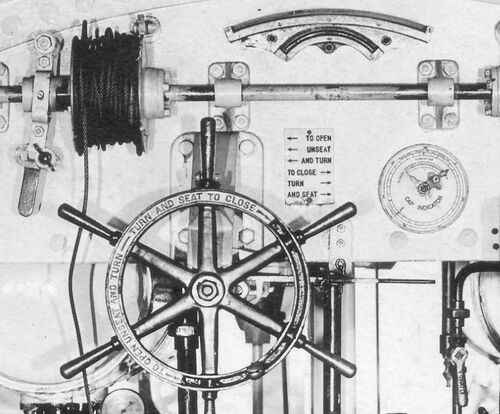

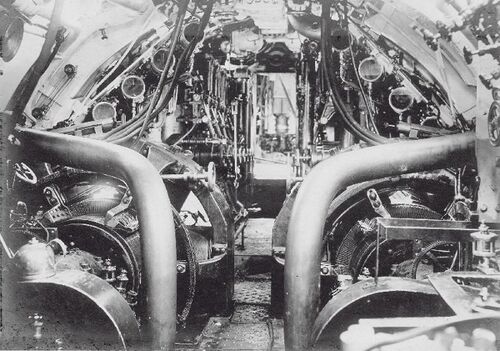

Detail of the port torpedo loading winch cable drum at the image top. To the left is the handle that allows the drum to be selected for use while leaving the starboard drum disengaged. There is a similar handle on the starboard cable drum to select or deselect that winch. The large hand wheel is used to open and close the rotating bow cap that acts at the tube muzzle door. At the top is an clinometer to show angles of list or roll the sub is experiencing. The dial on the right is a mechanical indicator for what position the bow cap is in. Behind the bow cap wheel to the left is a horizontal handle that is used to "seat and unseat" the bow cap into either the open or closed positions after it has been rotated. It appears to be chained into position.

U.S. Navy photo

Page created by:

Ric Hedman & David Johnston

1999 - 2023 - PigBoats.COM©

Mountlake Terrace, WA, Norfolk, VA

webmaster at pigboats dot com