Dolphin Control and Pump Room: Difference between revisions

Pbcjohnston (talk | contribs) mNo edit summary |

Pbcjohnston (talk | contribs) (Finished adding pictures) |

||

| Line 1: | Line 1: | ||

[[File:Header 169.jpg]] | —[[File:Header 169.jpg]] | ||

=== Control Room === | === Control Room === | ||

| Line 176: | Line 176: | ||

[[File:Dolphin Pump Rm-1b.jpg|left|500px]] | [[File:Dolphin Pump Rm-1b.jpg|left|500px]] | ||

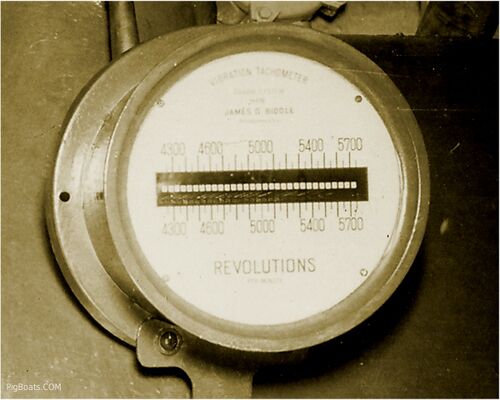

<div style="text-align: justify;"><span style="color:#00008B">Closeup of the tachometer for the trim pump. | <div style="text-align: justify;"><span style="color:#00008B">Closeup of the tachometer for the trim pump. | ||

<small>US Navy Photo Contributed by Roger Torgeson</small> | |||

[[File:Red bar sub new 2.jpg]] | |||

[[File:Dolphin Pump Rm-1c.jpg|left|500px]] | |||

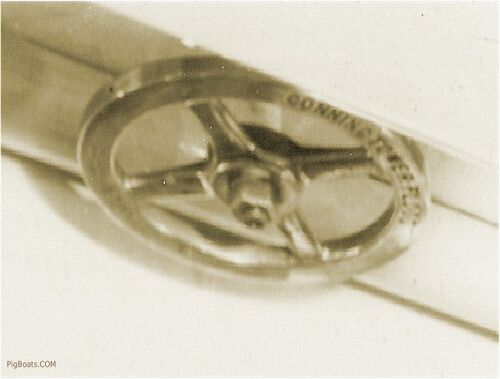

<div style="text-align: justify;"><span style="color:#00008B">Closeup of the manufacturer's plate on the trim pump. It is from the Electrodynamic Co., Bayonne, NJ. The rest is illegible. | |||

<small>US Navy Photo Contributed by Roger Torgeson</small> | |||

[[File:Red bar sub new 2.jpg]] | |||

<div style="text-align: justify;"><span style="color:#000000"> | |||

=== Pump Room Port Side === | |||

</div> | |||

[[File:Dolphin Pump Rm-2.jpg|left|500px]] | |||

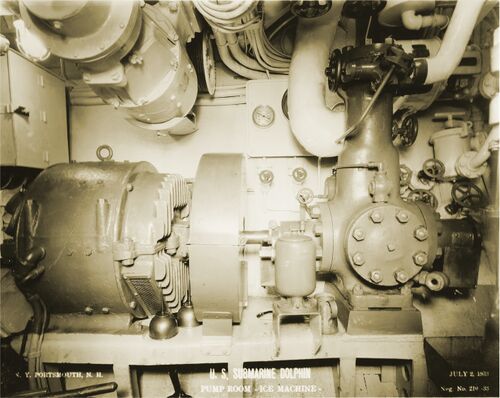

<div style="text-align: justify;"><span style="color:#00008B">On the port side of the pump room is the "Ice Machine" for refrigeration and freezing in the cold storage room. It was made by the "York Ice Machinery Corp". The York Corp. is still in business today. It should be noted that refrigerated storage for food was a luxury virtually unheard of on submarines in any other of the world's Navies. The long (70 days +) patrols in the warm waters of the Pacific that were anticipated for these fleet boats virtually required refrigerated storage. Without it, food could not be kept fresh for the entire patrol. | |||

<small>US Navy Photo Contributed by Roger Torgeson</small> | |||

[[File:Red bar sub new 2.jpg]] | |||

[[File:Dolphin Pump Rm-2b.jpg|left|500px]] | |||

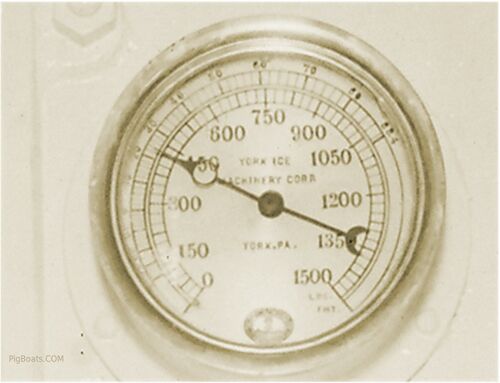

<div style="text-align: justify;"><span style="color:#00008B">Pressure gauge for the York compressor. | |||

<small>US Navy Photo Contributed by Roger Torgeson</small> | |||

[[File:Red bar sub new 2.jpg]] | |||

[[File:Dolphin Pump Rm-3.jpg|left|500px]] | |||

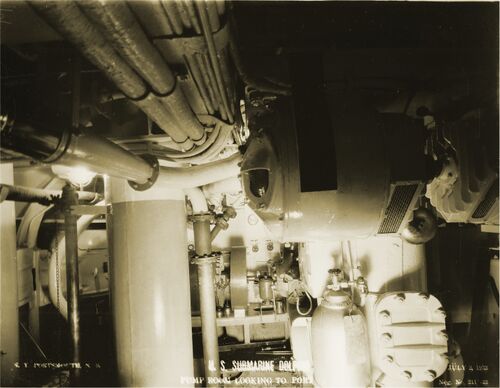

<div style="text-align: justify;"><span style="color:#00008B">View of the port side of the pump room giving a wider angle view. The York compressor is visible in the background. The flask seen in the right foreground could hold a variety of gases including Freon used in the York compressor. Forward is to the right. The Chill box and freezer are also to the right. | |||

The large vertical cylinder seen to the left side is the periscope well for the # 2 periscope. | |||

<small>US Navy Photo Contributed by Roger Torgeson</small> | |||

[[File:Red bar sub new 2.jpg]] | |||

<div style="text-align: justify;"><span style="color:#000000"> | |||

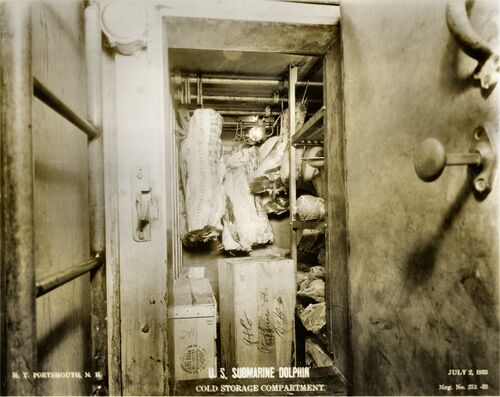

=== Cold Storage Room === | |||

</div> | |||

[[File:Dolphin Pump Rm-4.jpg|left|500px]] | |||

<div style="text-align: justify;"><span style="color:#00008B">The cold storage room. It isn't known if this was used as a refrigerator or a freezer. The slabs and sides of meat suggest it could be being used as a refrigerator. A ladder up to the Control Room is seen on the left. The quality of the food on the fleet submarines was excellent and it was envied by most other navies. | |||

<small>US Navy Photo Contributed by Roger Torgeson</small> | |||

[[File:Red bar sub new 2.jpg]] | |||

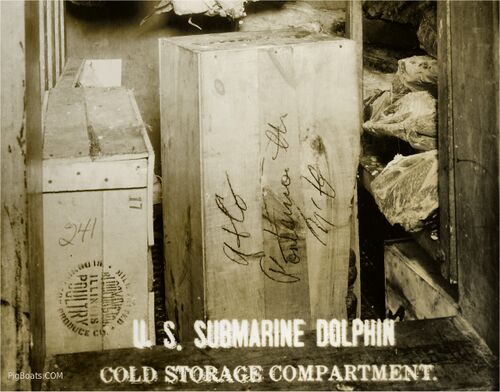

[[File:Dolphin Pump Rm-4b.jpg|left|500px]] | |||

<div style="text-align: justify;"><span style="color:#00008B">Close up of some of the contents. Whole sides and quarters of pork and beef have been placed in the room. It seems as though the cooks had to cut their own steaks and chops unlike today when it all comes pre-cut and prepared. | |||

<small>US Navy Photo Contributed by Roger Torgeson</small> | |||

[[File:Red bar sub new 2.jpg]] | |||

[[File:Dolphin Pump Rm-4c.jpg|left|500px]] | |||

<div style="text-align: justify;"><span style="color:#00008B">Close up of the bottom of the room showing wooden crates of poultry and more meats on shelves to the right. | |||

<small>US Navy Photo Contributed by Roger Torgeson</small> | <small>US Navy Photo Contributed by Roger Torgeson</small> | ||

Revision as of 20:40, 15 June 2023

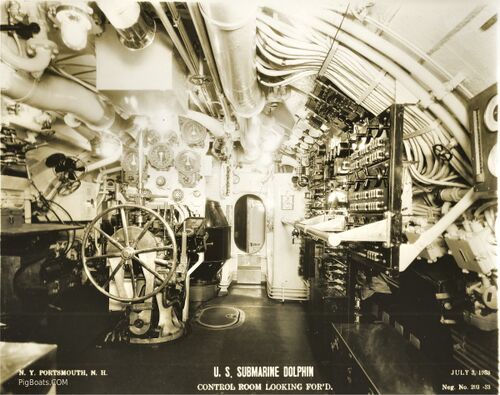

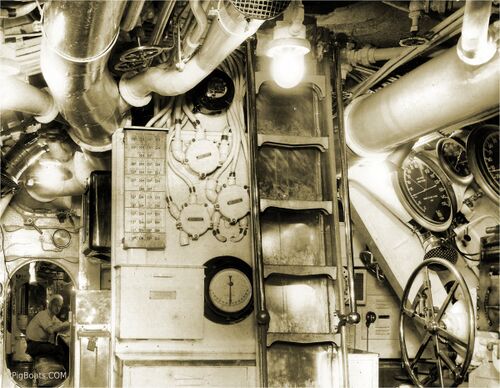

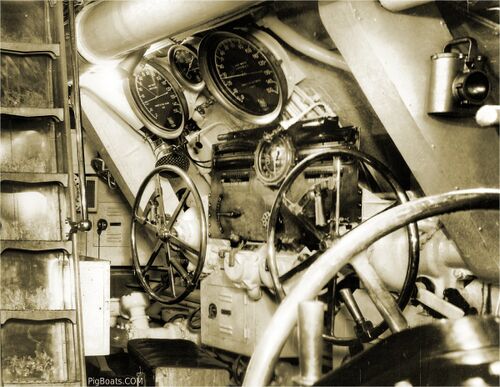

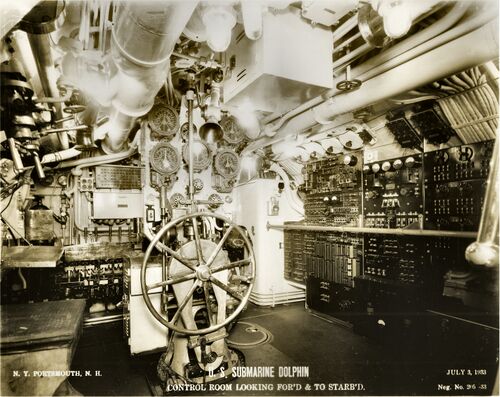

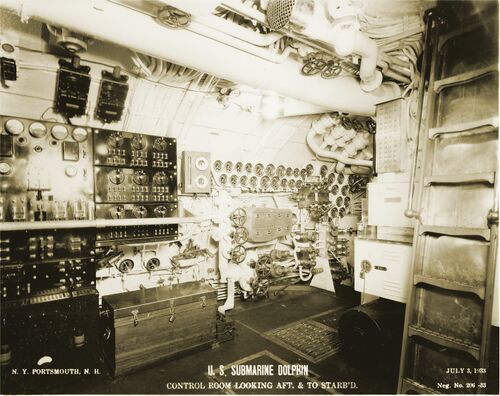

Control Room

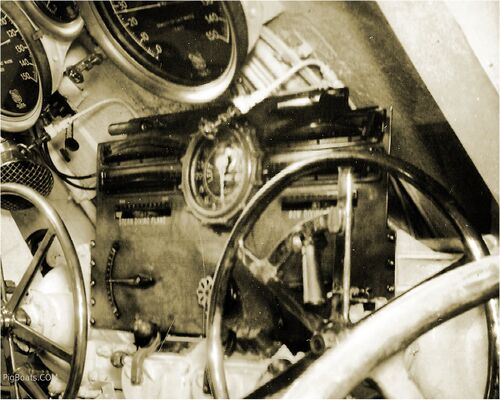

In the center above the helm wheel is the rudder angle indicator, flanked on both sides by the engine order telegraphs. The lever on the vertical shaft was used to engage/disengage the control room helm from the conning tower and bridge helm. Which helm would have been the primary station for submerged operations? We would lean towards the conning tower, but that opinion might be flavored by what was done in combat in WWII and may not necessarily reflect pre-war 1930's practice.

Large levers next to helm are for switching from normal hydraulic to hand hydraulic. In hand hydraulic you spun the wheel to develop hydraulic pressure and this was a very laborious process.

Oval hatch in deck next to helm most likely leads to a store room. Note speaking tube to conning tower above the helm.

US Navy Photo Contributed by Roger Torgeson

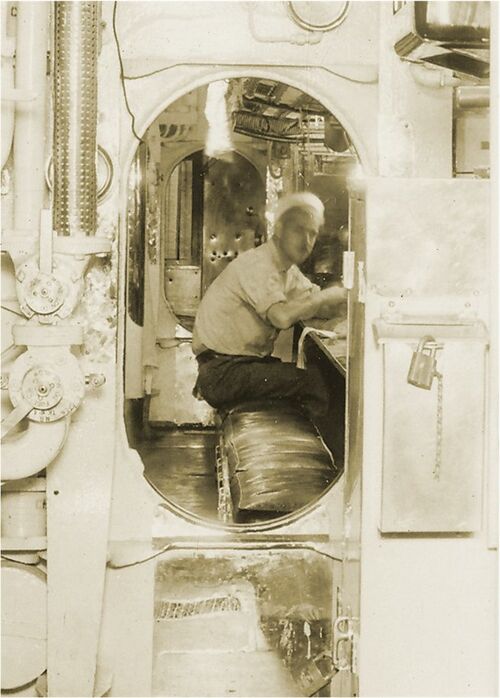

Open grate in the deck leads most likely to the Pump Room and the grating is for drainage of any flooding into the Pump Room, where it can be pumped out through the main drainage system.

The square hatch is suspected to be the access to the Cold Room/Freezer. The padlock seen on the hatch seems to correspond to other food storage areas with padlocks making us think this is that space. Drawings indicate that the Cold Room/Freezer was directly under the middle of the Control Room.

On the right edge of the photo, just below the polished bell of the speaking tube, and above the battle lantern, is the mechanical linkage for the bow planes coming out of the angled enclosure just above and to the right of the bow planes control wheel.

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

The large, angled sheet metal enclosures, to the left and right of the stern planes and bow planes wheels, cover the mechanical linkages for the stern and bow planes control rods.

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

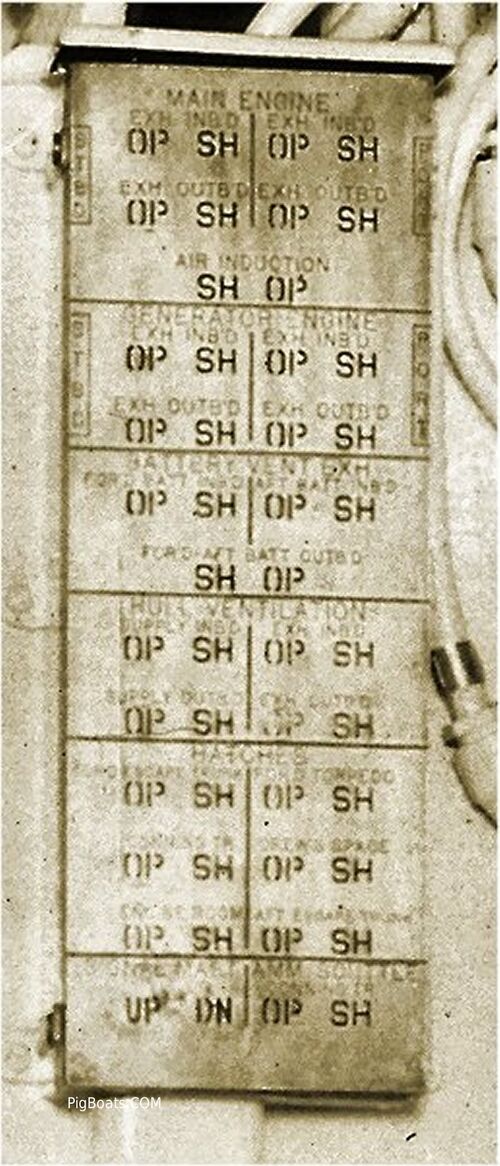

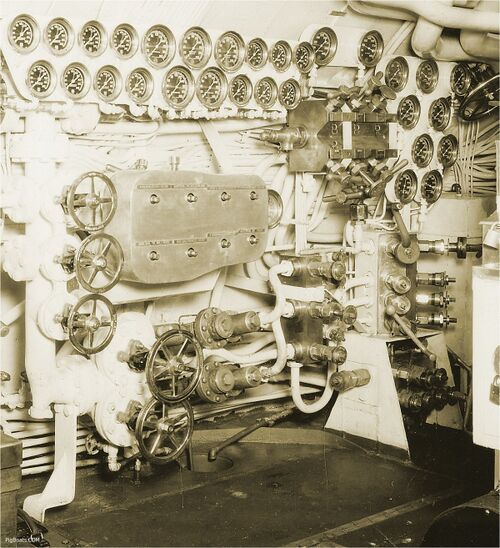

Just to the right of these panels is a barometer. This was important to letting the crew know what was happening with weather but also in letting them know the submarine was closed up properly for diving. When all hatches and valves were closed a small amount of air was bled into the submarine and the barometer would register this pressure change. If everything was closed properly the pressure would not change. The report; "Pressure in the boat", would signal all was well and the dive could proceed. An important piece of equipment indeed.

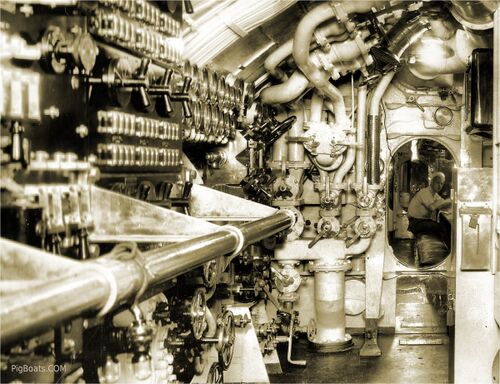

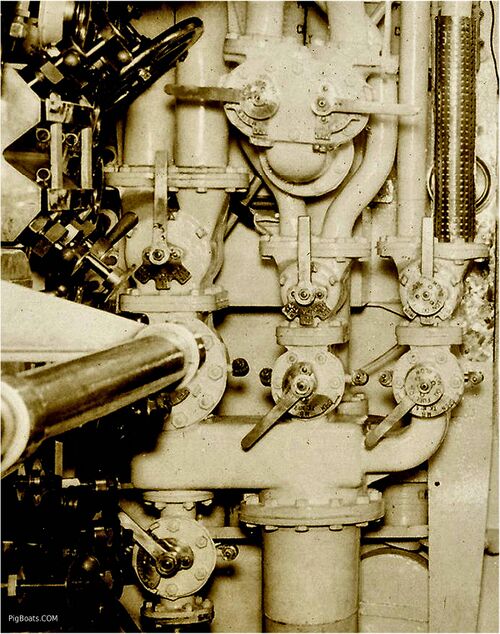

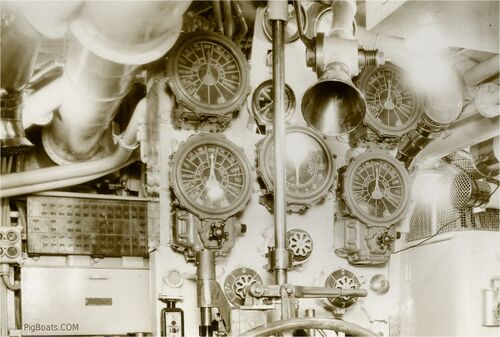

Moving right we see the row of gauges for the air system and air banks and various pressures. The manifold seen below these gauges is the trim manifold which ports internal ballasting water around the boat. Air system valves are to the right and below of this manifold.

The row of large valves and piping seen in the overhead are associated with the Fuel Ballast Tank System.

US Navy Photo Contributed by Roger Torgeson

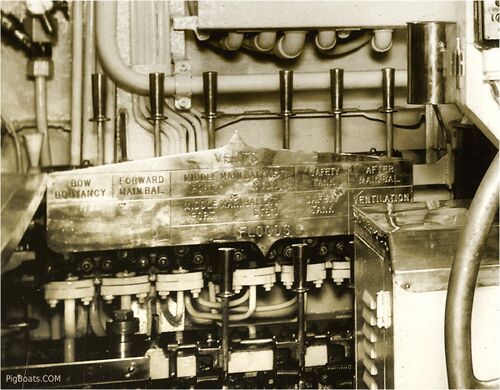

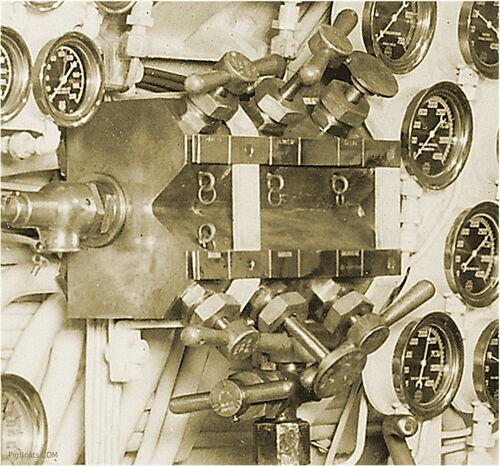

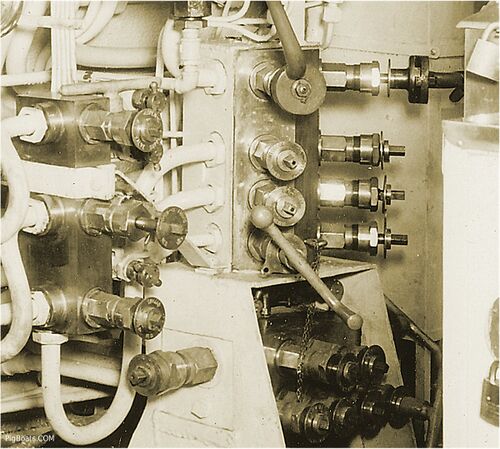

Labels on the trim manifold, top row of valves: "Aux Bal, Tk No1 Blow", "Aux Bal, Tk No2 Blow", "For'd Trim Tank Blow", "Aft Trim Tank Blow". Bottom Row: "Aux Bal, Tk No1 Vent", "Aux Bal, Tk No2 Vent", "For'd Trim Tank Vent", "Aft Trim Tank Vent". The three valve handles on the left read, Top: "200# Air For'd" and the bottom one reads "200# Air Aft". The center handle has nothing readable except "open" The bottom large handle says "200# Air From Reducer" Meaning Higher pressure air was sent through a reducer to become 200 pound air.

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

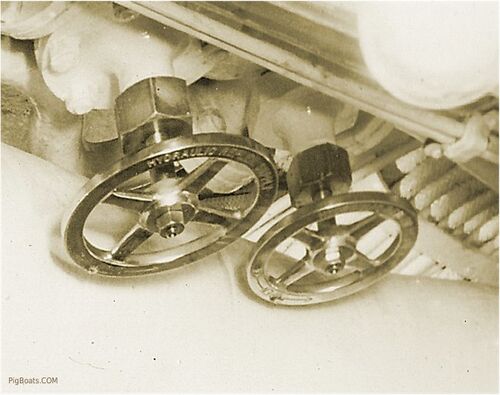

This is the earliest mentions we have seen to anything dealing with a hydraulic system on a submarine. The valve wheel says "Hydraulic Refill Supply". The other valve is unreadable. What this hydraulic system ran is not known at this time.

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

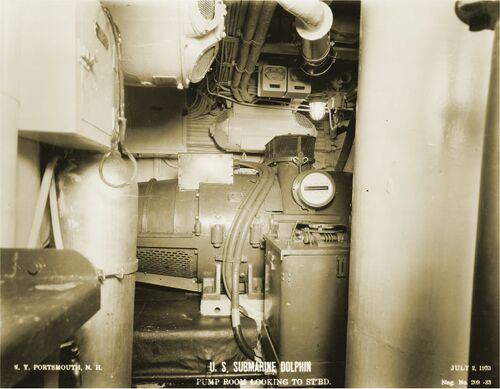

Pump Room Starboard Side

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

Pump Room Port Side

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

The large vertical cylinder seen to the left side is the periscope well for the # 2 periscope.

US Navy Photo Contributed by Roger Torgeson

Cold Storage Room

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

US Navy Photo Contributed by Roger Torgeson

Page created by:

Ric Hedman & David Johnston

1999 - 2023 - PigBoats.COM©

Mountlake Terrace, WA, Norfolk, VA

webmaster at pigboats dot com